Pelagic processor Denholm Seafoods has placed an order with Skaginn 3X to supply a newly-designed multifunctional ValuePump in a deal that is the result of months of research and development carried out by the two companies.

The new pump design can handle 60 tonnes of pelagic fish per hour. The genuinely innovative aspect of this project is the sheer scale of the equipment and the distance that the product is conveyed for further processing.

‘We are incredibly excited to start using the ValuePump. It will not only accommodate our high-capacity operation, but will also create value while transporting our product from A to B, as we will be chilling and sanitising the product whilst conveying it to further processing,’ said,’ says Richard Duthie, Denholm’s Commercial Director.

‘The ValuePump will also eliminate the use of trucks used to transport from the harbour to coldstore, which is very beneficial.’

The pump will move the product 200 metres from the docks to Denholm’s facility in Peterhead through a 16-inch diameter pipe.

‘The design, development and implementation of the 16-inch ValuePump was certainly a challenge, but the outcome is truly remarkable,’ said Skaginn 3X Regional Manager Ragnar Arnbjörn Guðmundsson.

‘We’ve spent months testing the pump, and I’m pleased to report that it has the proven capacity to convey 60 tonnes per hour over a distance of 200 metres, which is exactly what our clients requested. Most importantly, it handles the product gently along the way, ensuring that the quality of the fish is maintained throughout.’

The ValuePump has been in production by Skaginn 3X since 1994 in various iterations, but last year the company began researching and testing a new and improved design intended to work with the capacity required by Denholm.

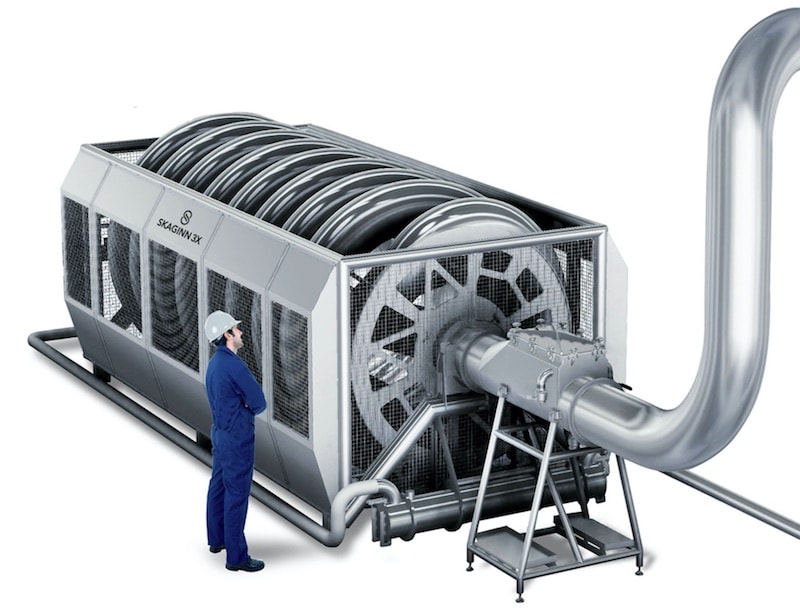

The pump’s basic function is based on Archimedes’ screw, also known as a screw pump. Primitive screw pumps were used to move low lying water through a cylinder to elevated irrigation ditches.

Based on this fundamental concept, the ValuePump conveys product gently through a closed, low-pressure pipe system. The conveyance is carried out in a liquid medium, which varies depending on application, but may take form of water, fluid ice or an additive solution.

Requiring about six times less energy consumption in comparison to conventional pumps, the ValuePump process creates substantial energy savings for the seafood processor.

‘Not only will the ValuePump help save energy, but it will also replace trucks used to transport product from the docks to Denholm’s facility,’ Ragnar Guðmundsson said.

‘Making this an environmentally sound enhancement, which is very important to our client. We are continuously developing the ValuePump and we are currently working on various projects for the salmon industry.’

Slow revolutions rotate the internal pipes, which are filled with the liquid medium and product, flushing the contents towards the outgoing pipe. This enables the system to deliver product to higher elevations without using a propeller. Instead, material is gently conveyed in a closed system without exposure to the outside environment.