When the original supplier for the hull of new German-flagged, Swedish-owned pelagic trawler Kristin NC-336 unexpectedly dropped out, this brought both bad news and good for the owners and Karstensens Skibsværft, which expected to complete the new vessel for its Donsö-based owners.

As the hull construction was switched to Karstensen’s own yard in Poland, the delay also coincided with changes in German regulations relating to fishing vessel capacity, with the allowable tonnage limit raised from 800 to 1000gt, making it possible to extend Kristin’s capacity before construction had begun.

The owners of operating company Kristin Fischereigesellschaft mbH are mate Örjan Carlsson and skipper Ola Hansson, along with Örjan Carlsson’s son-in-law Dan Bergman who sails as chief engineer, all based on the island of Donsö in the Swedish pelagic heartland of the archipelago off Gothenburg.

Kristin’s hull arrived at the yard in Skagen in January this year and was delivered to its owners in July, having completed successful sea trials.

Built to the yard’s own design, the 53.55 metre LOA Kristin has an 11.20 metre moulded breadth and a 1080 cubic metre capacity in eight RSW tanks. The owners have fishing opportunities for both industrial and human consumption species, and expect to operate on sprat, sandeel and herring across a number of fishing seasons.

The increasingly stringent quality requirements for both industrial and human consumption landings mean that a great deal of focus has been placed on the RSW facilities, as well as on optimising working and living conditions, and coming up with an optimised operating profile to ensure minimal energy consumption.

The deck equipment choice went to an all-electric MacGregor Rapp Marine system with twin 50 tonne trawl winches and a pair of 60 tonne net drums lined up to the hydraulic stern hatches and guide rods. Rapp Marine also supplied the 38 tonne tail-end winch, mooring and anchor winches, and the net sounder winch, as well as the two 16 inch electric fish pumps – a first for the region’s fleet – and the drums for the fish pump hose and power supply.

SeaQuest supplied the forward 4t/16m and the aft 4t/12m deck cranes.

Catches in the eight tanks are chilled by the double Johnson Controls (JCI), 2×700 kW/2×605,000 kCal/h RSW system. The vacuum pump system is from Önnereds Welding and has two 66kW compressor units and twin 2800 litre tanks.

Kristin’s power arrangement is in line with the thinking applied to recent Karstensens deliveries, working on the principle that the full propulsion power and full power to the winches are not needed at the same time.

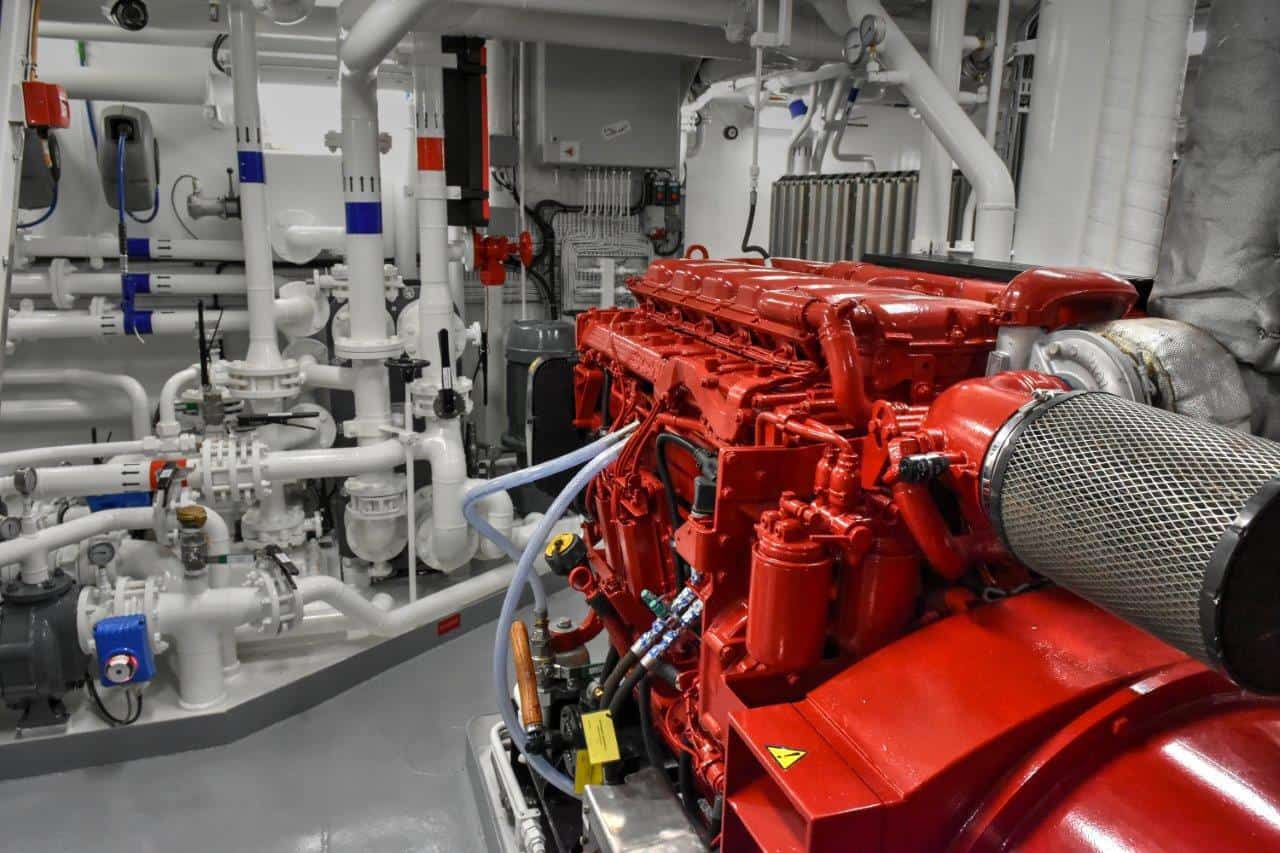

The main engine is a 2309kW MaK 8M25 driving a 3800mm diameter Cat Propulsion (Berg) MPP850 propeller via a Reintjes LAF 4555 reduction gearbox, which has a PTO powering a 1200kW n AvK Cummins DSG 86 shaft generator which is intended as the primary power supply.

While fishing, with the electric winch system in more or less continuous use, the PTO and shaft generator are engaged. When full power is needed for the winches, there will not be a need for full propulsion power, so the arrangement allows the main engine to serve as the power source for both propulsion and power supply, without the need to run auxiliaries.

In the event that there is a need for additional power to the propulsion system, then one of the two 400kWe Scania DI13 can supply the ship’s normal power supply as well as the winch system in towing mode.

As the electrical system is prepared for load-sharing/parallel coupling of the 2 generators, there is be a great deal of security built into the system, as these together are able to meet the vessel’s power requirement.