New technology to support seafood production in exposed offshore locations could unlock an additional £4.2 billion in turnover for Scotland’s aquaculture sector, following the results of a pioneering research project led by start-up Impact-9 into options for wind turbine sites to double up as salmon farms.

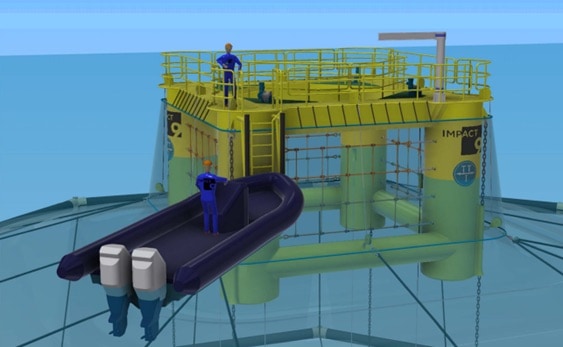

The company’s Net9 system – a submersible, floating structure which utilises the ocean’s natural ecosystem and conditions – is one step closer to becoming a commercial reality, with a proven design concept now ready to be tested at scale.

The breakthrough marks the end of the latest phase of the £200,000 Inflatable Marine Products for Aquaculture Containment Technology project (IMPACT), which was funded by the UK Seafood Innovation Fund (SIF) with additional support from the Sustainable Aquaculture Innovation Centre (SAIC).

Engineers from Tension Technology International (TTI) and blue economy project developer Simply Blue Group were also involved in the development work, looking at regulatory issues and fish health and welfare as well as the cost challenges associated with bringing aquaculture into open ocean environments.

At full scale, a single Net9 pen could be used to produce up to 2500 tonnes of salmon per annum, with oxygen-rich waters and conditions that mimic the wild helping the fish to thrive. Impact-9 has identified an opportunity to use the new technology within existing and planned offshore wind energy zones, where a small portion of these zones – around 12 x 12 km – would be enough to house 280 pens and quadruple Scottish production.

The position of wind turbines is typically determined by water depths, currents, and the need to avoid shipping lanes, which are also factors that would influence the suitability of a location for offshore aquaculture.

‘A move further offshore can pave the way for a new sustainable seafood industry of scale, worth billions of pounds in the UK alone. The economic potential is similar to that of offshore wind, however, it will occupy a relatively small amount of ocean real estate and could fit in with existing and planned offshore wind turbine arrays,’ said John Fitzgerald, CEO of Impact-9.

‘In the same way that lithium-ion batteries are the key to green transport, we believe that smart flexible structural elements like those used in Net9 will be the enabler of offshore seafood production. The most exciting part of this phase of work was to see the positive cross-over between fish welfare and structural engineering. The potential for stormy weather is of course unavoidable in these environments, but the design of the system allows the net and the fish contained in it to move together with much more flexibility than a rigid structure.’

Impact-9’s system uses a flexible structure designed to move with the waves and weather any storms, rather than fighting against the water, reducing the potential stress on fish.

Next year, the research team plans to begin building a unit suitable for technical demonstration at the European Marine Energy Centre (EMEC) in Orkney, which will also provide interested producers with an opportunity to see a model of the system in operation.

‘This is part of a systematic engineering approach to address technical novelty and undergo carefully managed tests to qualify that new features will perform as desired,’ said Tom Mackay, engineering manager at TTI.

‘The process is similar to offshore renewable systems development, and we have brought to bear expertise from that sector to help Impact-9 manage the risk of adopting their novel structures in the Net9 application.’