Trawling is currently being hit with a double whammy – on the one side it is being slapped with trawling bans due to increased pressure to prevent seabed damage and, on the other side it is being engulfed in rapidly rising fuel bills due to it being one of the more fuel-hungry fishing methods. Both of these contribute towards increased consumer concerns and resistance to trawled products.

Maurice Shenker, of Active Fishing Systems South Africa, certainly believes his new generation Active Trawl System (ATS) could be the “lifeboat” the industry needs right now. He said: “The ATS is the only trawling system (both in current use and near-future deployment) which, by virtue of its design, construction and operation, can significantly reduce the destructive impact of trawl gear on the seabed and, at the same time, do this using a lot less fuel.”

Development of the system was started more than 15 years ago and has now reached a point where the technologies to make it work are ready and proven, and the concerns as well as suggestions of potential users have been addressed. For instance, the original concept called for an extra cable for power and communications. The fishermen that were consulted were strongly against this. Besides the operational and safety issues that this would have created on board, it was also pointed out that it could become an additional hazard to seabirds. Another concern was the robustness and survivability of the Variable Thrust Vector Doors (VTVD’s)for bottom trawling.

After looking at a number of possible options an elegant and innovative solution to the cable problem was found which allows unlimited operational times with all the features and benefits of the original system. However, there is no such thing as a free lunch and, in this case, the advantage of removing the cable was offset by an increased number of moving parts on VTVD’s. However, when looking at the overall picture particularly with the increasing concerns about seabed damage, the situation was turned around from a win-lose into a win-win state of affairs.

The structure could have easily beefed up by using tougher materials and thicker sections as well as by adding more shrouds and guards, but this would have also increased the costs considerably. Instead, a conscious decision was taken to leave the VTVD’s relatively light and unprotected so that, if they were continuously in contact with the seabed, they would suffer damage.

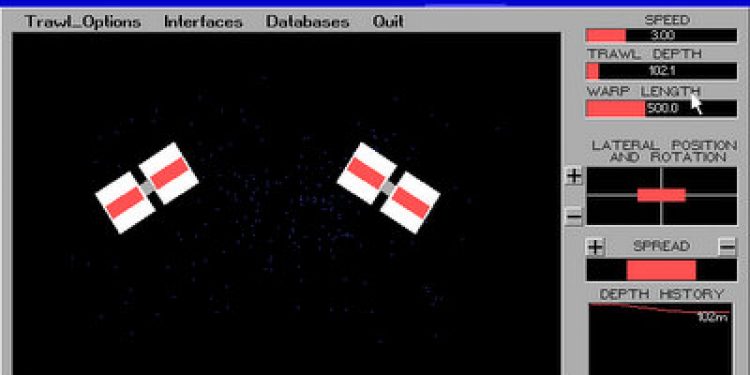

In normal operation, the VTVD’s would be controlled to ride a few meters off the seabottom with the trawlnet rigged and weighted to lightly touch the bottom. In other words, the design intent of the ATS is to keep the VTVD’s off the seabed. Nevertheless it is very important to strike the correct balance between making the system sufficiently “hard” to withstand the rigours of normal trawling and handling operations and, making it “soft” enough such that damage repair costs act as an effective deterrent to running the VTVD’s on the seabed.

Keeping the VTVD’s off the seabottom has another advantage – it requires less fuel. But this is not the only way it saves fuel. Maurice Shenker went on to say: “Trawling with the ATS is very much like having an automatic cruise control as well as an accelerator pedal and steering wheel.”

The cruise control would take care of most of the routine adjustments, ensuring that the VTVD’s generate the minimum forces to keep the net mouth at its optimum and at the correct depth. Should, for instance, the trawl speed increase, the cruise control would adjust the output forces of the VTVD’s to suit these new conditions. This is totally different to what happens with conventional trawl doors where the forces generated are always proportional to the square of the speed and, in many cases, the additional forces due to the increase of trawl speed exceed that required for the optimal net mouth opening. This results in additional drag and hence extra fuel and the possibility of a distorted net with less catching ability.

The overriding accelerator pedal is another useful tool in the quest for fuel economy. For instance, when hauling the trawl, one can take the foot off the gas so that the trawl can be hauled up faster with less effort. When trawling, one can push harder on the pedal in order to lift the net to avoid an obstacle or to intercept a higher swimming shoal. One can also use the steering wheel to move the trawl laterally to sweep a more productive area in a similar way that a racing car moves from side to side to “widen” itself to prevent overtaking by a chasing driver.

In effect, the ability to easily and quickly move the trawl up and down as well as side to side means that one can use a smaller net with a corresponding reduction in towing power.

All of the above plus the hydrodynamic efficiency of the VTVD’s could contribute significantly towards reducing overall power consumption and hence reducing fuel costs.

The question is often raised as to whether the concept of trawl control at the door end of the warps by means of controllable doors is a better option than the typical “autotrawl” trawl speed and warp length control. The theoretical aspects of trawl door control have recently been investigated in a SINTEF study entitled, “Precise Control of Trawl Systems”. In essence, this study supports the concept of control at the trawl doors and also provides useful guidelines for further implementation thereof.

On the practical front, there is definite movement towards this. Besides the ATS, there are at least two other systems being developed, one in Europe and another in the USA. “It is interesting that we have all chosen different technologies to achieve the control required,” said Maurice Shenker. “This is great as it does not “lock in” the concept to one particular control method.”

Being a small R&D company, Active Fishing Systems does not have the resources and facilities of the above companies and this has undoubtedly slowed down development of the ATS. While local trawling companies have readily offered to make trawlers available for prototype sea trials, there has not been to date the committed financial “buy-in” necessary to get the project off the back burner. Considering the negative reports about the fishing industry that regularly seem to make news headlines as well as the current economic conditions, this is not unexpected.

It is, however, a project which truly encompasses the aims and the spirit of programs and themes of organizations and institutions such as ICES-FAO and the European Commission, that support mitigation measures against seabed impact damage by mobile fishing gears as well as the development of new fishing technologies. The fact that the development to date has taken place in South Africa should in no way detract from its potential worldwide application.

There is still a fair amount of work to be done before the system could be commercially available and therefore cooperation and collaboration with role players, fishermen, manufacturers, regulators and investors from all around the world on this project is welcomed.