The largest trawler to be built at Macduff Shipyards maintains a long connection between the yard and Mark Lovie of the Venture II Fishing Company.

This is Mark Lovie’s fourth Macduff trawler in a series that started with the wooden-hulled Venture, built as Endeavour II in 1993. Since then the steel-hulled Venture II in 2001, Venture III in 2017 and now Venture IV have each been the largest vessels built at the yard at various points.

The new Venture IV BF-326 is the yard’s largest newbuild in terms of both size and gross tonnage.

The newbuild process began in 2020 when he went to the yard looking for options for a new vessel to replace his previous <24m registered trawler, as well as seeking improvements in fuel efficiency, speed, sea keeping, and crew comfort. The yard’s design team knew that a larger vessel would be needed to meet all these requirements and the outcome was a design for a 34.50 metre, 10.50 metre breadth trawler.

Macduff Ship Design carried out the design work and the finalised plans went to the Finomar Shipyard in Szczecin, where the hull was fabricated, and this arrived at the yard in Macduff for outfitting in the late summer of 2021. Outfitting took roughly one year, and Venture IV went to Fraserburgh for its final coat of paint before the final round of sea trials and handover to Mark Lovie and his crew just before Christmas – just time enough for two short shakedown trips.

Venture IV is fishing with a 4.50 square metre pair of Vónin Storm trawl doors, a Thyborøn clump and with a set of trawls and rigging supplied by Jackson Trawl, who also supplied the warps.

Venture IV is arranged with four deck levels and is closely based on a series of successful predecessors with proven performance behind them. The additional length compared to Mark Lovie’s previous vessels provides welcome extra space for processing areas, a high capacity fishroom without the need to stack high, and generous cabins and crew areas.

The aft engine space houses the 1110kW Yanmar 6EY26W main engine coupled to a free-standing Mekanord 650HS gearbox with a reduction ratio of 5.44:1, driving the 3300mm Kumera Helseth controllable pitch propeller which turns inside a low-drag, high-thrust nozzle with a triple rudder system to provide high turning force. Scan Steering supplied the MT5000 steering.

Electrical power is supplied by a pair of Yanmar 6NY16L gensets, each delivering 280ekW. The main engine and generators are cooled via freshwater plate coolers. The hydraulic towing pumps along with stern thruster are also fitted within the engine room along with the main electrical switchboard, refrigeration and the ships pumping systems.

The midships fishroom can take 2000 stacking boxes, is chilled by a Premier Refrigeration plant and chiller system, and two 2.5 tonne Geneglace icemakers feed into the large ice lockers which can hold up to 10 tonnes of flake ice.

Venture IV’s deck is laid out with twin trawl ramps with hydraulic gates and a clump bay incorporated into the structure. The three 10-tonne trawl winches with capacity for 2250 metres of 26mm warp are located amidships, with the mid-wire winch on the starboard side. The trawl winches are controlled by a Pentagon autotrawl. The trawl blocks at the stern are mounted on tracks, allowing these to be offset up to 1.20 metres from the transom, reducing the strain on the steering gear when working along an edge.

The deck machinery and hydraulic package are from MacGregor places three 20-tonne sweepline winches in the stem to provide maximum working space on deck. There are three 12-tonne bagging winches, a pair of 10-tonne codend winches and three 13-tonne gilsons. A couple of 6-tonne gear handling winches are mounted aft, plus three smaller ones forward. MacGregor also supplied the 12.30m telescopic boom landing crane with 2.30-tonne winch.

The shelterdeck runs the full length, although this is mainly open aft and provides a perimeter walkway. There is a a full breadth casing amidship for the skipper’s cabin, two two-berth cabins and electronics room. The large wheelhouse occupies practically the full width, allowing excellent visibility, and this includes full-height windows on the centreline to provide a complete overview of the trawl deck below. Woodsons of Aberdeen supplied the wheelhouse electronics for Venture IV.

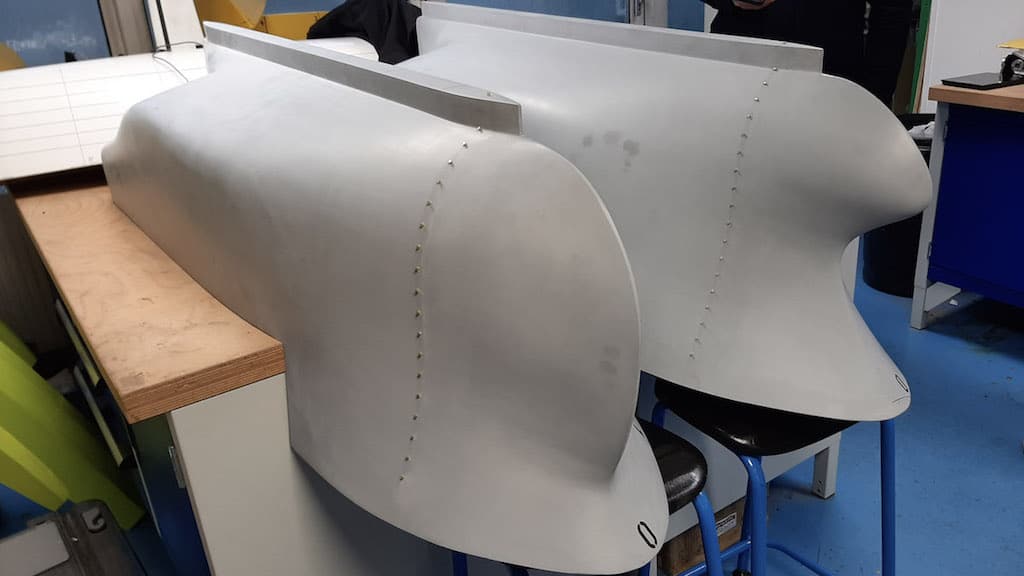

During the design process the decision was taken to study the performance of various bow designs in relation to speed and sea keeping, making it possible to optimise the hull. A series of tests were carried out at the Wolfson Unit in Southampton, comparing two hulls of similar overall length.

The first featured a conventional hull with bulbous bow and flared stem, and the second a hybrid bow with an inverted bow for the majority of the stem but still retaining a small flared portion at the top to keep the foredeck dry.

Two scale models were manufactured and then trialled in the Solent University Towing Tank at a range of different speeds, in both calm water and simulated waves representative of the areas which the owner operates. The results from the trial showed a decrease in hull resistance in calm water, mainly due to the increase in waterline length of the new bow.

More notably, the modern bow indicated a significant reduction in both resistance and motion when being towed into a head sea with waves, particular at higher speeds above 8 knots. During Venture IV’s first trips off the west of Scotland, early indications are that the hull is performing as anticipated with increased speed, reduced fuel consumption, and improved seakeeping.