Marel is pleased to announce that its long-term partner, Icelandic Group, has purchased the new FleXicut water-jet cutting robot for high precision bone detection and removal.

Equipped with high resolution X-ray and two water-jet cutters, as well as a traditional cutting blade, the FleXicut incorporates two critical processing steps in one machine: precisely locating the pinbones and then cutting the fillet to remove them.

Icelandic Group will be the first to install this revolutionary technology, when the machine is set up in its Ny-Fiskur processing facility in Sandgerdi, Iceland. Not only will FleXicut enable Ny-Fiskur to produce bone-free products with virtually no manual handling, it will also broaden the processor’s range of product possibilities.

The automation of the whitefish bone removal process with FleXicut is set to transform the whitefish industry by reducing the need for skilled labor as well as improving product handling and yields.

The FleXicut can perform a variety of cutting patterns thanks to the flexibility of using water-jets for the bone removal process, and the angle cutting option allows it to follow the curved lines of the bone frame very closely, thereby further reducing pinbone material. This means significant yield gains in the loin – the most valuable part of the fish – while greatly increasing value due to less manual handling throughout the process, thereby adding significant value for Marel’s customers.

Icelandic Group is a leading international seafood company that builds on over 70 years of expertise in the Icelandic fisheries and offers a wide variety of seafood products and services on a global scale.

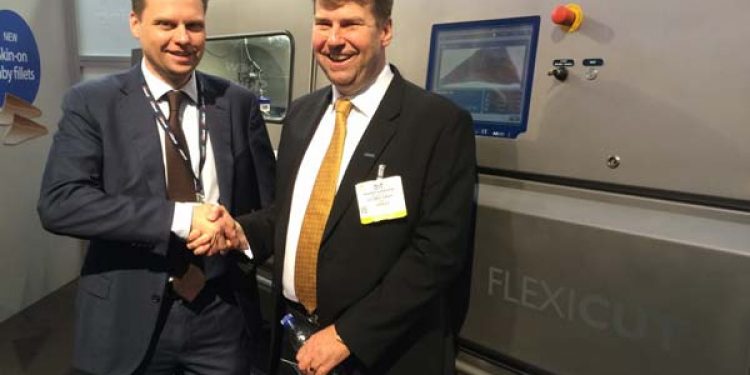

Marel and Icelandic Group share a long history of innovation through partnership, and this investment reflects Icelandic Group’s ongoing commitment to Marel. FleXicut is an exciting step forward for the whitefish industry and this deal will add even more momentum to the continuing development in coming months.

The pre-launch of FleXicut is being held at Marel’s Stand 4-6227 at Seafood Processing Global 2014 this week, where Marel is also demonstrating a wide range of equipment and software solutions that help fish processors optimize raw material utilization, ensure traceability and food safety, and improve processes throughout the value chain.