Working with sub-suppliers Velfag, Marel and Afak, Skaginn 3X has been chosen by HB Grandi as the main contractor to fit out the factory deck of its new vessel now under construction in Spain. The name of the vessel has not yet been revealed, but according to our sources it is codenamed RE1.

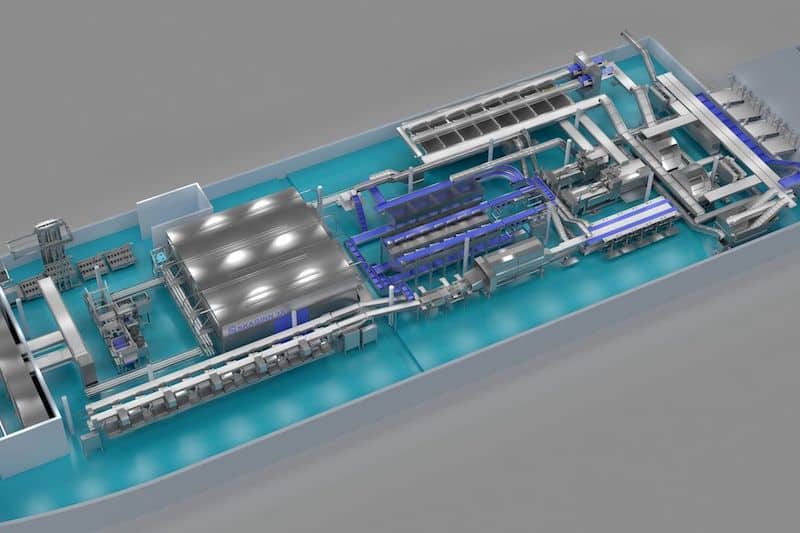

Skaginn 3X and HB Grandi have finalised an arrangement under which Skaginn 3X takes overall responsibility for the processing deck. This will feature a high level of flexibility in working easily with a variety of species, with processing choices as well as different options for packing.

‘A waterjet cutter provides the possibility of new end products previously not feasible in at-sea processing. It is very important that the design of the next steps in processing, including the packing line, the design of the freezers, box handling and palletising, also support the new and expanded possibilities,’ said Jón Birgir Gunnarsson, head of marketing and sales at Skaginn 3X.

He commented that this is the fourth consecutive Skaginn 3X project for HB Grandi fishing vessels. This follows the catch handling systems and unmanned fishrooms of fresher trawlers Engey, Akurey and Videy, delivered by the Celiktrans yard in Turkey.

Astilleros Armon Gijon acts as a total supplier of the vessel and as such, will deliver the processing deck from Skaginn 3X as a part of the overall delivery. Skaginn 3X will act as the main supplier and system integrator of the processing deck with some components delivered by key suppliers such as Velfag, Marel and Afak.

Skaginn 3X managing director Ingólfur Árnason said that the agreement and the unique design of the processing deck are the result of close co-operation between the Skaginn 3X team and the team at HB Grandi.